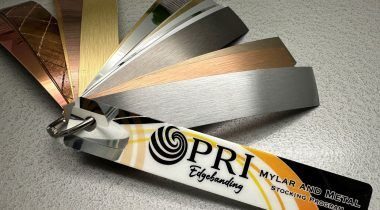

Mylar and Metal Edgebanding

PRI Edgebanding stocks all of your mylar and metal edgebanding solutions. Elevate the aesthetics and durability of your products using our high-quality metal and mylar edgebanding. Find the latest and most unique patterns and designs, as we frequently update our catalog to include all of the most popular and sought-after edgebanding finishings.

Enhance Your Products with Premium Quality Finishing

Are you looking to protect those unfinished edges on your metal project? Do you need to protect the edge from wear and tear while reinforcing the integrity of your piece? Or maybe you want to add some metal edgebanding for decoration and an added aesthetic? We can help you find the right edgebanding to complete the job.

PRI Edgebanding has various mylar, metal edgebanding, laminated mylar 4×8 sheets, and metal high-pressure laminate available for our valued customers. When you have a metallic project, please get in touch with the PRI Supply sales team. We can value source the best options for your project’s edgebanding and panels. Technical specification sheets are available on all of our listed products.

Mylar Edgebanding Specifics

Mylar edgebanding is a thin film laminated to a plastic backer, usually ABS or PVC. The mylar film resembles real metal and is available in a brushed and polished finish. Mylar film gives projects an attractive metal-like appearance that is less expensive than purchasing real metal.

On all of the mylar edgebanding we provide, there is a protective peel coat on top of the banding, which will prevent scratching to the edgeband during your production process. This edgeband also has a primer on the back, similar to PVC and ABS, which helps the edgeband stick to your desired product. It is available in automatic, pre-glued, and PSA.

Mylar vs. Real Metal Edgebanding

Both mylar and metal edgebanding are produced on wide master rolls, allowing you to have edgebanding slit to any width. The mylar master rolls are 24” wide, and the metal edgebanding rolls are typically 7” wide, which provides a great deal of flexibility, depending upon the needs of your project.

Both mylar and metal edgebanding can be produced in thicknesses ranging from .5mm up to 3mm. Most existing stock programs are in either .5mm or 1mm thicknesses. Others can typically be ordered on a custom basis with production minimums.

They also come in various choices, including aluminum, stainless steel, gold, chrome, pewter, zinc, bronze, and copper edgebanding. The mylar and metal edgebands look very similar, but mylar is more economical as it is a film instead of a thin, real metal surface.

Applications of Mylar and Metal Edgebanding

The following are common-use applications of mylar and metal edgebanding:

- Whether you’re aiming for a sleek, modern cabinet or a trendy, industrial retail display, our edgebanding options will meet your design needs.

- Mylar edgebanding offers a smooth, resilient finish that protects and beautifies edges.

- Metal edgebanding provides a robust, stylish accent that stands up to heavy use.

- Both materials are ideal for various applications, from furniture manufacturing to interior design, ensuring your creations look professional and last longer.

- Our high-quality edgebanding not only improves the aesthetic appeal but also reinforces the structural integrity of your pieces.

Choose from our extensive range of styles and finishes to perfectly match your project’s vision. Use it today for your boat and RV interiors, custom furniture and cabinets, exhibits and tradeshow booths, interior design projects, and retail displays and fixtures. Experience the superior performance and visual appeal of mylar and metal edgebanding with us today.

Why Should You Choose PRI’s Mylar and Metal Edgebanding?

Unmatched Quality

We take pride in providing superior-quality materials that ensure durability and longevity. Our mylar and metal edgebanding are manufactured using state-of-the-art technology, keeping the quality unmatched.

Versatile Design Options

We offer extensive styles, patterns, and finishes to complement any design aesthetic. Whether you seek a contemporary, classic, or custom look, our range of mylar and metal edgebanding will meet your unique requirements.

Automatic Application

Are you looking for something different? Or do you have a particular type of mylar and metal edgebanding you prefer? No worries. The PRI Edgebanding stocking program allows you to source the edgebanding you want while beating any metal edgebanding or mylar edgebanding pricing you receive from other edgebanding vendors

Start Your Edgebanding Project Today

PRI Edgebanding stock orders all the metal edgebanding you desire, from gold edgebanding to bronze edgebanding, chrome edgebanding, and more. Take your furniture, interior design, and more to the next level, adding that special something — premium edgebanding.

Explore all the styles, sizes, and thicknesses of mylar and metal edgebanding that PRI Edgebanding stocks. Our premium quality finishing is sure to upgrade all of your projects.

Testimonials

Hear firsthand customers’ experiences working with the PRI Supply team in their testimonials below.

“Just want to let you know the edgebanding is working out great!! It’s doing exactly what I was hoping it would do. I would like to thank you again for taking the time for me last week. I felt leaving that I had made another great business partner for my company with your help. I wish I would have found your company sooner. I will be getting all the stuff as needed from you in the future.”

– Modern Cabinet Making, LLC